Tri Environmental

Biography

Sam Allen is a professional with a background in chemical and materials engineering, with a specialization in the fields of polymer testing and geosynthetics. Presently Mr. Allen serves as the President and Director of the TRI Environmental Group, a series of global geosynthetic and geotechnical laboratories and service centers providing routine conformance testing services, chemical resistance testing as well as sponsored research and development projects supported by government and private industry.

Mr. Allen has a long service record to the International Geosynthetics Society (IGS) and currently serves as the IGS President. He is a member of ASTM International’s D35 Committee on Geosynthetic Materials. Over the last two decades, Mr. Allen held committee leadership positions including D-35 Chair, Vice-Chair and Sub Chair and Membership Secretary. Mr. Allen also currently serves as the Convener of Working Group 5 on geosynthetic durability within ISO TC221. In addition, he serves on the Board of Advisors of the Geosynthetics Institute in Philadelphia, Pennsylvania.

Masterclass Description

Recent discussions and updates of GRI GM13/GM17

GRI GM-13, Test Methods, Test Properties and Testing Frequency for High Density Polyethylene (HDPE) Smooth and Textured Geomembranes, and GRI GM-17, Test Methods, Test Properties and Testing Frequency for Linear Low Density Polyethylene (LLDPE) Smooth and Textured Geomembranes have achieved acceptance and adaption in many markets and countries throughout the world. The documents have been modified over time with 16 and 14 modifications/revisions, respectively. The testing protocols and frequencies have been updated and are not the primary focus of this paper. However, over time the barriers market has expanded in scope and range; currently there is a significant range of geomembrane applications that vary greatly in duration, expected performance levels and associated properties.

A “one size fits all” approach, while appropriate in the past, is no longer adequate to address the industry’s existing and growing needs. While it is understood, and in fact mentioned in the specification documents, that the values can be changed for differing applications. But in practice, this rarely occurs. Further, there are some requirements and statements in the document that are no longer appropriate for the current broad range of applications.

Further, there are multiple pathways and formulations that exist to attempt to meet the specification requirements. Most of these pathways are appropriate and an outcome of differing markets and techniques. Some manufacturers however are optimizing “performance to the specification”, as contrasted with optimal performance for the applications: in the long run, this is a disservice and does harm to the geosynthetics industry.

This paper describes testing and data evaluation efforts on behalf of the Geosynthetics Institute to prepare 5 “levels of performance”, or classifications, for geomembrane barriers based on application requirements including, but not limited to durability, lifespan, barrier properties and other factors. The existing requirements of GRI GM 13 and GM 17 are modified for each performance level. Significantly, included in the work was the exploration of opportunities to shorten the time required for important durability test measurements using available testing technologies and global standard approaches. Several examples of this work will be presented.

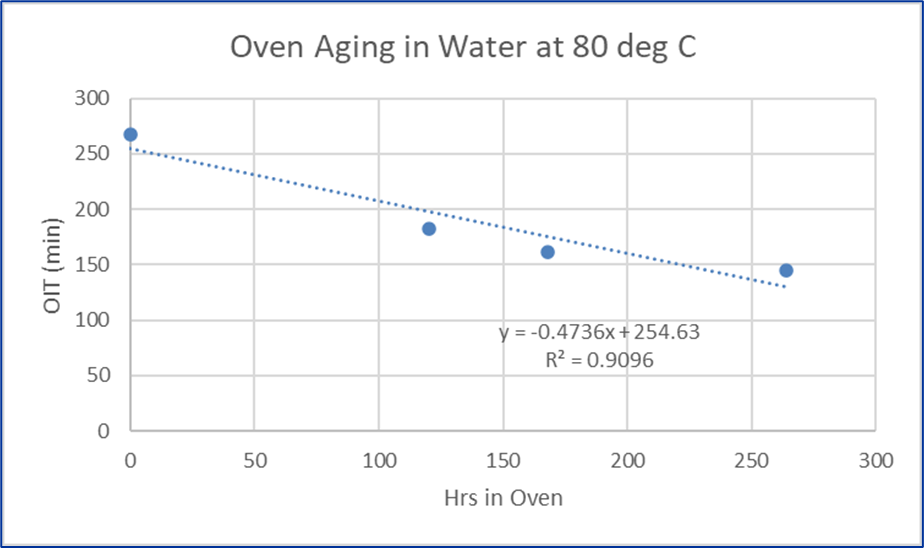

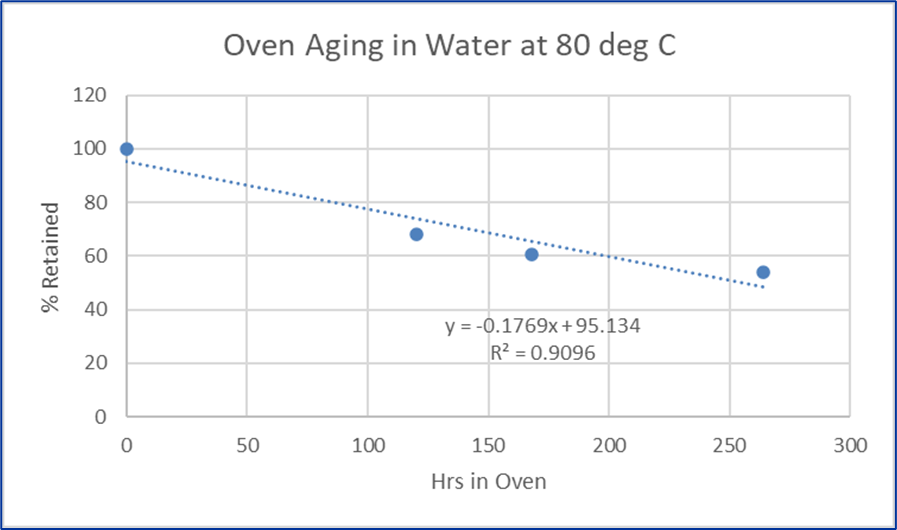

(a)

(b)

Figure 1. (a) OIT vs Time for various samples exposed in elevated temperature water, and (b) percent OIT retained for the same data. GRI GM 13 Spec. specifies percent OIT retained as 55% which correlates to 226.9 hrs above, or 9.5 days. Conclusion: Encouraging alternate to the D5721 90 day exposure.

New specification requirements were also considered and proposed, but not for other than the most critical of applications. The process included investigation of existing databases from multiple sources and review and discussion of the proposed levels and values. The five proposed geomembrane specifications will be presented and explained.

The benefits of this effort are both economic and sustainable. This effort holds the opportunity to assure that the Geosynthetic Institute’s documentation and specification recommendations remain both valuable to the members and the industry as well as frequently used both in the near and longer-term future.